Printing on disposable Syringes

|

Disposable syringes are one-time usable medical consumable. Hypodermic syringes have a hollow needle attached to a syringe which helps pierce the skin and inject medicines into the bloodstream. However, they can also be used to extract blood and other fluids from the body. Legislation Title 21, of the Code of Federal Regulations (CFR), governing the labelling and coding of syringes is an essential safeguard that protects the health of patients. Syringes are made up of clear PP (Polypropylene) (clarified medical grade).

|

|

|

Scale and logos are printed on them for calibration. PP is a plastic from the family of polyolefins with a surface tension of 30.9 mN/m. And, clarified PP is the specialized Polypropylene which has glass like clarity, excellent moisture barriers properties, hot filling capacity and low cost, making it the ideal packaging material for food, beverages, optical media, house wares and medical products. To a great degree, ink adhesion depends on the surface energy of the substrate, which must be greater than the surface tension of the ink. Polyolefins, such as polypropylene and polyethylene, have a low surface energy and need to be pre-treated to raise the surface energy. Generally three methods can be used: Flame, Corona or Plasma treatment to improve ink adhesion.

Colours used in syringe printing are generally Black/Blue/Red.

|

|

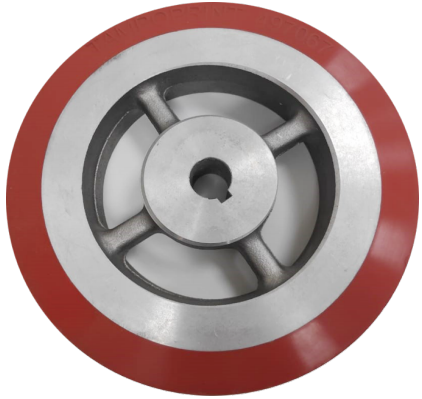

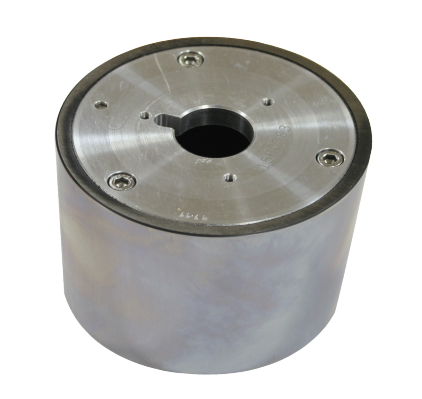

Pad printing makes markings, scales and decorations possible where other processes reach their limitsRotary Pad Printing:

Ink is applied on an engraved roller which is cleaned by a blade to trap the ink inside which is subsequently picked up by a rubber roller. This rubber roller comes in contact with the syringe barrel to deliver the print. The printing line has been designed for printing on disposable syringes with different diameters. The output is 16.000 - 20.000 parts / hour, depending on the size of the syringes

|

|

Pad printing makes markings, scales and decorations possible where other processes reach their limitsRotary Pad Printing:

Syringe printing Ink must have following properties to deem fit for printing application on syringes:

Compliance with non toxic norms like EuPIA Exclusion Policy,

REACH regulation (SVHC) , Swiss Ordinance (SR 817.023.21), Canadian Hazardous Products Act (R.S., c.H-3, s.1.), USP Medical Class VI (exclusively for black T-200), Compliant with the current European standard EN 71-3 , Compliant with the current European standard EN 71-9 (exclusively for basic color shades T-200, white and black), RoHS compliant (2015/863/EU) // (2011/65/EU).

Free from heavy metals, formulated free from BPA, phthalate-free, fluorine-free, bromine-free.

Must be opaque.

Must adhere to P.P. with or without pretreatment.

Must be able to dry fast enough just to transfer on just to transfer on syringe. If slow then it will get smudged and if too fast, then it will dry on the steel roller or the rubber roller.

Must be able to sustain EOG or ethylene oxide gas sterilization

Additional additives to improve adhesion to PP available

*Pl. test before using & use as per TDS.

For more information

Mail : info@spinksworld.com Call : Helpline 9810626626

Disclaimer: This disclaimer informs readers that the views, information, and opinions expressed in the text belong solely to the experts or professionals working in the same field of study. However, the customers are required to test for themselves before going into productions. All the presented information stems from the rich and varied 30+ year’s experience of organization in printing business. |

|

RUCOINX UV/LED Inks: A Safer, Smarter Choice for the Future of UV Printing

In a market increasingly shaped by regulatory changes and rising health standards, RUCOINX UV/LED inks are setting a new benchmark for safety and inno

Printing Solutions for Medical Supplies

What are Syringes? Syringes are made up of clear PP (Polypropylene) (clarified medical grade). PP a is plastic from the family of polyolefin

Special inks for Braille printing

Braille is a system of raised dots for people with vision impairment who use their sense of touch to feel the dots with their fingers in order to read

Printing Inks for Glass

Made in Germany Most of the organic inks for Glass are 2K (two-part reaction) inks and require post-heating process. However in summersmost inks ar

Ampoule Printing

Printing of Medical Ampoule strips: Machines & Inks. ( Spinks World Solutions ) What is an ampoule? An ampoule is a small hermetically seale

Printing on Feeding Bottles

We Introduce ourselves as value added solution provider for all the decoration needs of your products. A careful research & investigation is in